Massilly Services

The Project :

Create quality visuals for already existing machines and to comes. These visuals are used internaly and also on public exhibits to attire people

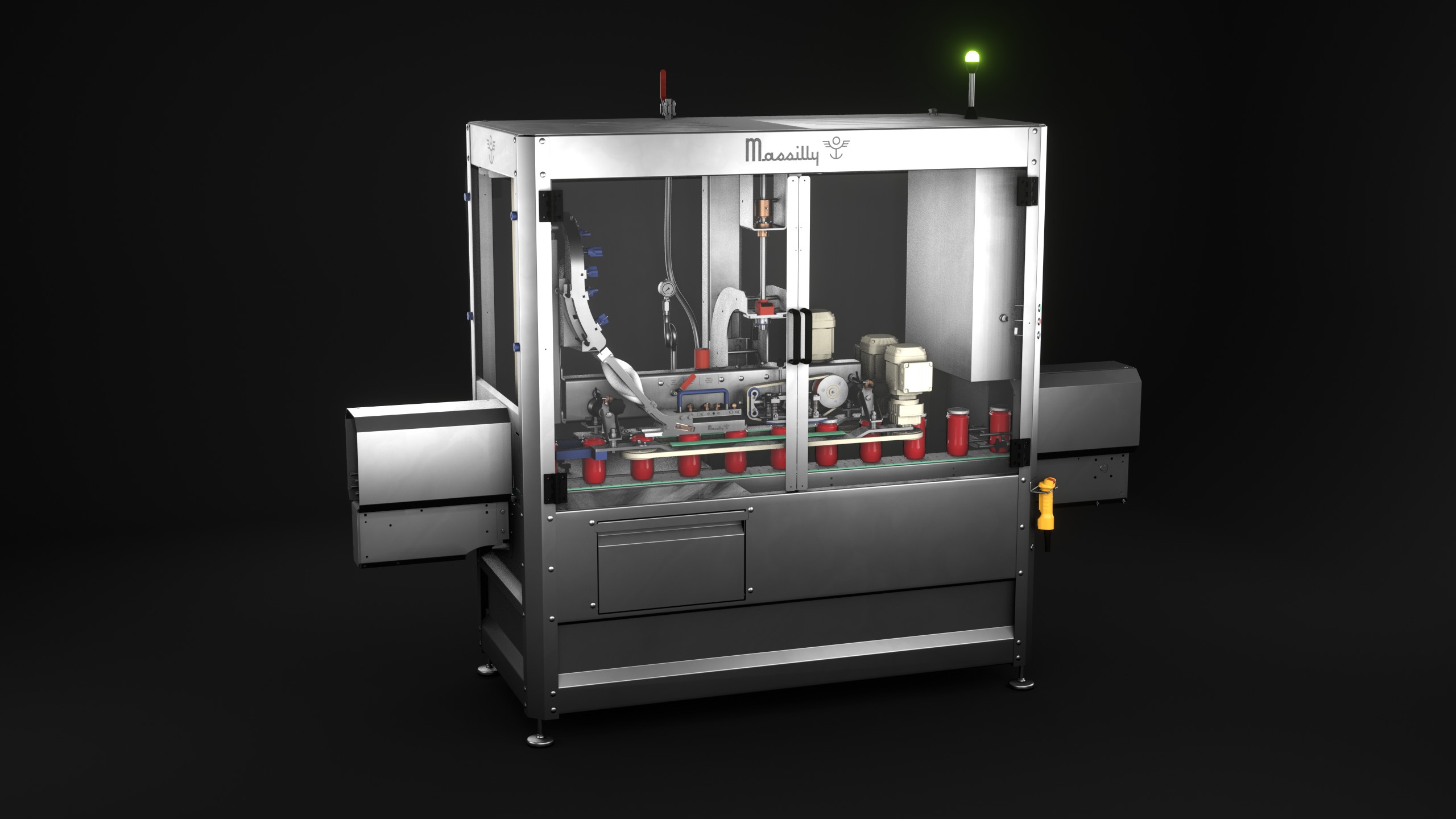

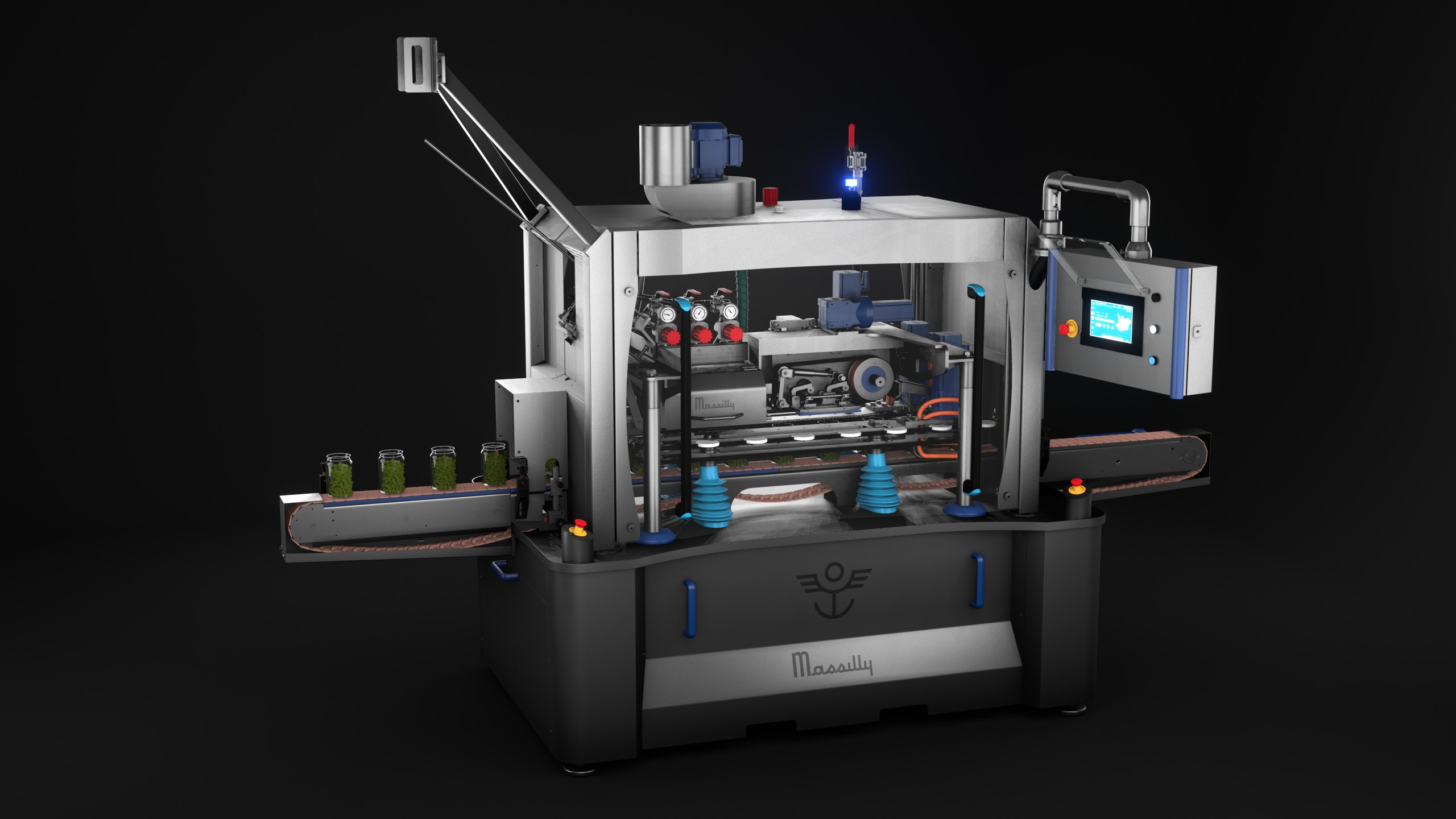

MY-CAP 500

- 3.000 Jars /h

- The change of wearing parts is done in less than 4 minutes

- The innovative steam flow system allows low steam consumption

- An ergonomic capsule loading thanks to the integrated elevator

- The ergonomics and accessibility of the machine allow a change of format in less than 5 minutes

MY-CAP 3000

- 25.000 jars/h

- Remote maintenance is provided via secure modem.

- Fully automated capping machine using brushless and I/O link technologies

- The innovative steam flow system allows low steam consumption

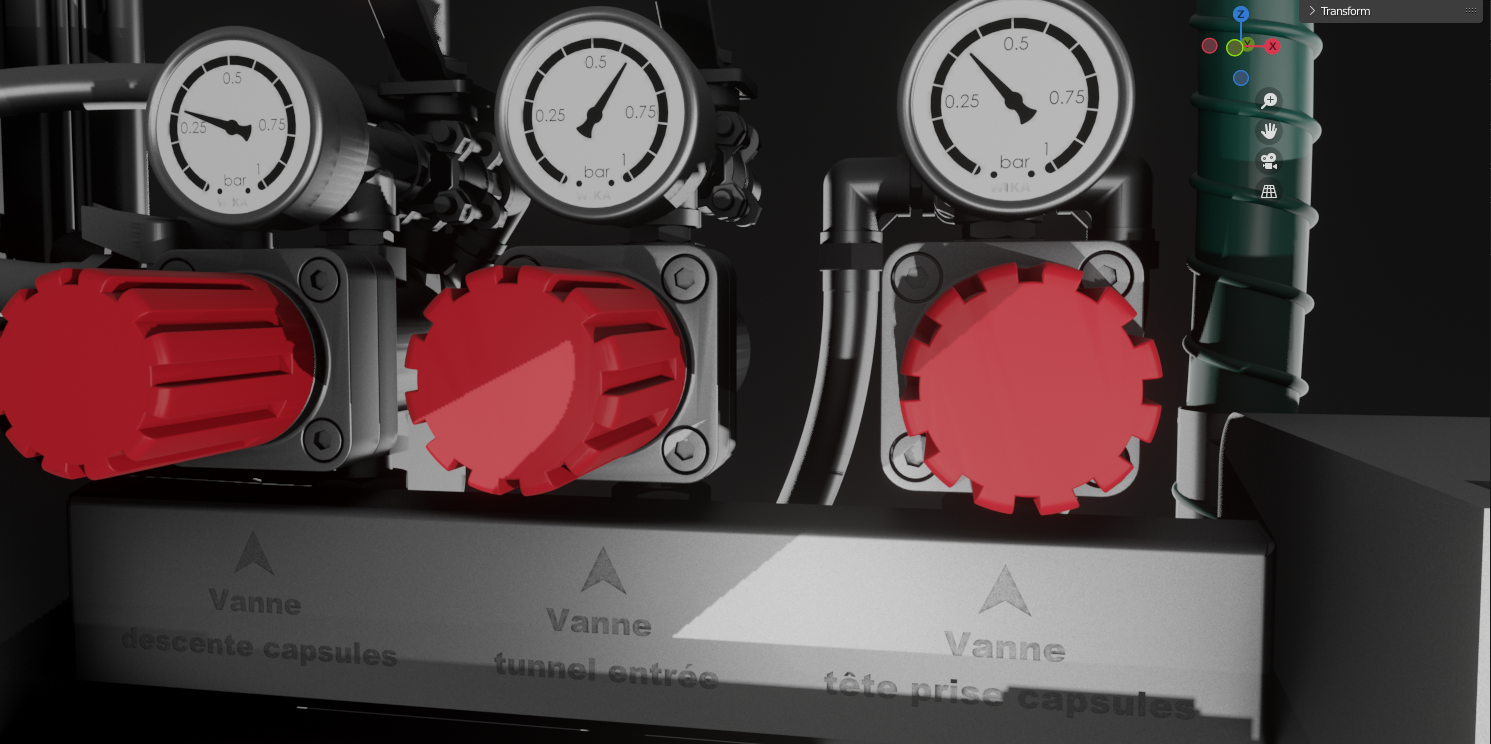

- The differential speed of the gears allows for optimal tightening

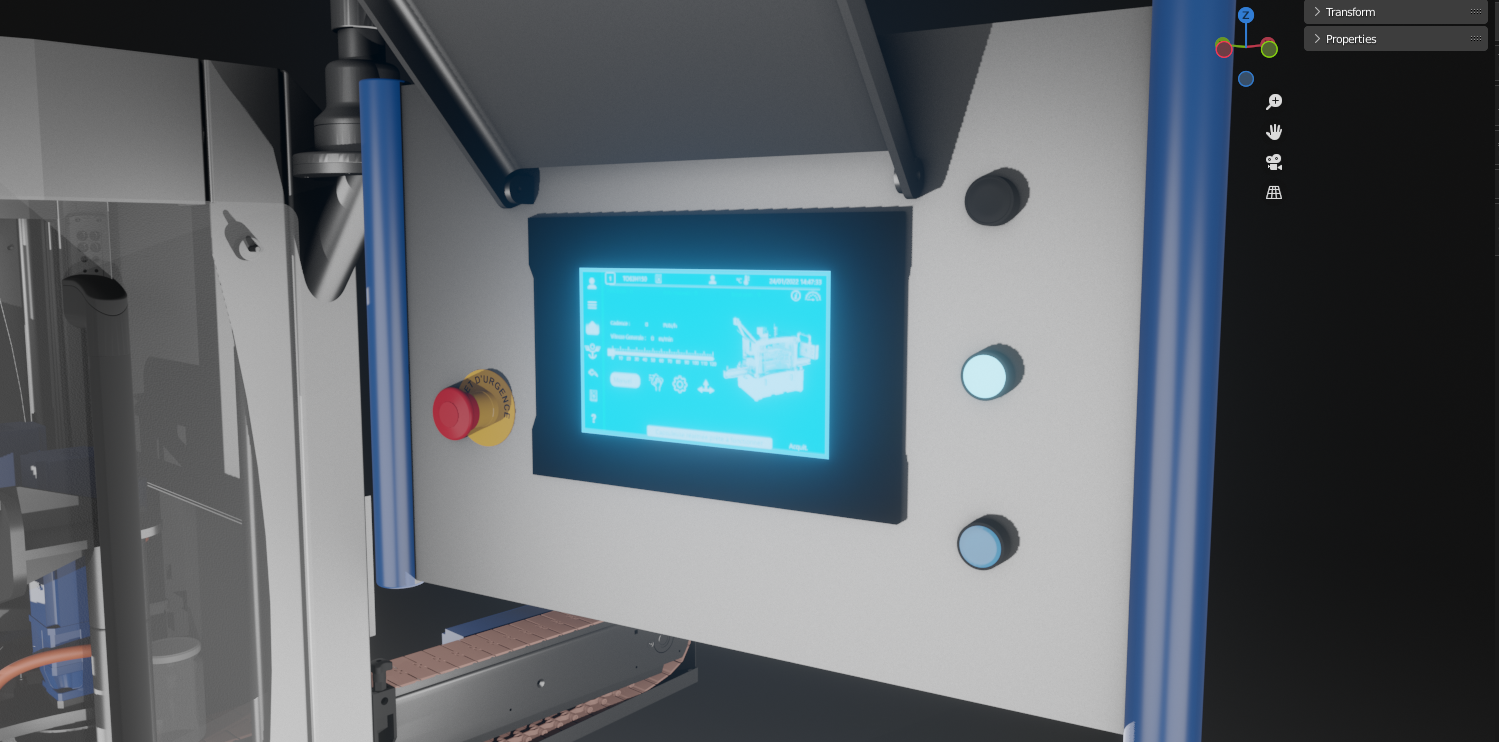

- The 9” touch screen allows for intuitive handling, maintenance assistance and easy management of the 40 available recipes

- The ergonomics and accessibility of the machine allow a format change in less than 3 minutes

- The change of wearing parts is done in less than 4 minutes

- The supervision allows for feedback of production information accessible on HMI or on your system

MY-CAP 5000

- 30.000 Jars /hours

- Automatic pot twist off capper

- Router for remote control by our technicians

- Versatile, reliable and safe for everyday use

- Total accessibility for optimized set-up, cleaning and maintenance times

- Quiet machine < 85 dBA

- Energy-saving mode

- Recipe settings configurable via HMI

- New generation of gears for portion jars

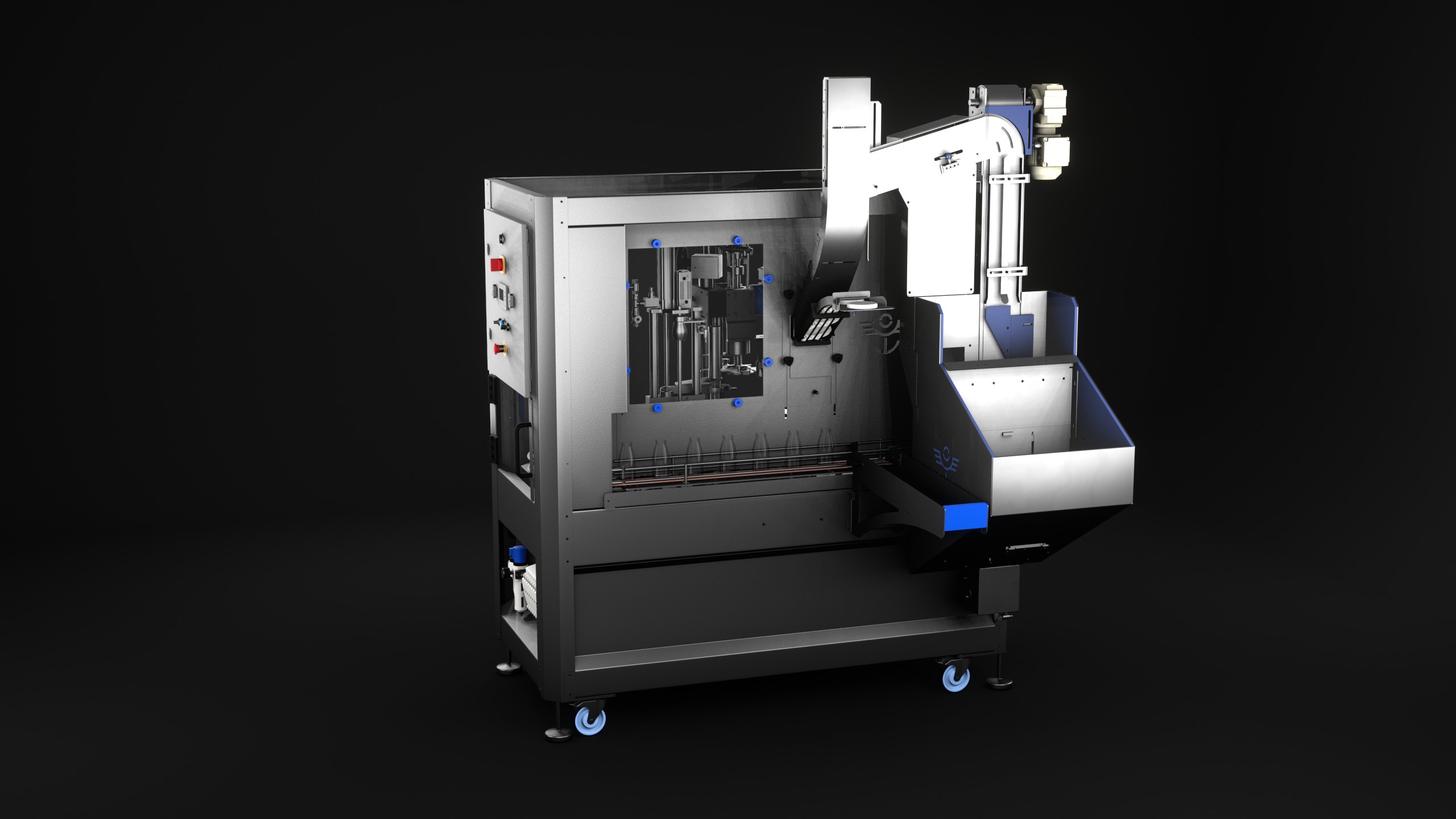

MY-LINE MICRO

- 1.200 Jars /h

- This set can be associated with your dosing machine and/or your pusher

- This micro-line, whose compactness (1900 x 1000 mm overall without options) and ergonomics have been particularly well thought out, aims for a nominal rate of 1000 units/hour (subject to the finished product and format), this with only 1 operator

MY-LINE MINI

- 1.500 Jars /mn

- Accessibility is optimal to allow format changes, cleaning operations at the end of the shift (hopper mounted on a pivot to be cleaned outside the enclosure perimeter) and maintenance (possibility of remote diagnosis via a secure connection).

- This mini line, whose compactness (2800 x 2100 mm overall) and ergonomics (total peripheral protections) have been particularly well thought out, aims for a nominal rate of 1500 units/h (subject to the finished product and format), this with just 1 operator.

Gallery :